Recent Challenges to Aerospace Parts Manufacturing & Their Solutions

Posted by Mike Sterling

Oct 22, 2021 4:54:50 PM

Topics: Ardel News

While machining technology is always advancing, 2020 accelerated some key innovations. In the machining industry, many companies had to pivot and produce necessary supplies quickly, or they were met with a decreased demand for products and were forced to reduce jobs. Even in the best of times, it's getting more difficult to find manufacturing workers, and companies are turning to automation. Using robotics to increase productivity is one of several trends and changes that are likely here to stay.

Topics: Machining, Ardel News

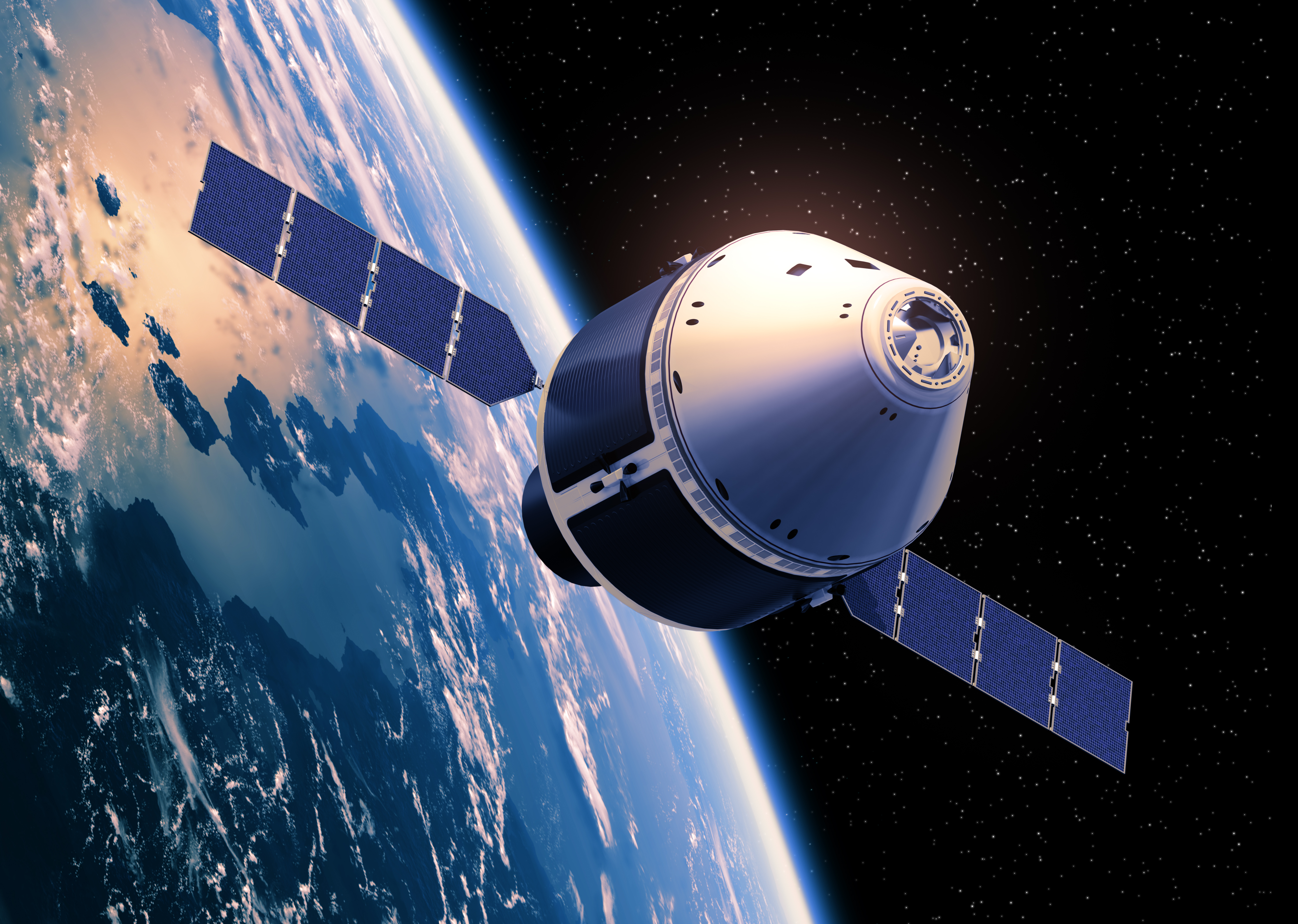

The Role of Machined Components in Satellite Communications

Posted by Mike Sterling

Jun 30, 2021 11:49:44 AM

Over the years, satellite communication systems—also known as satcom systems—have become increasingly important to our day-to-day lives. Since they allow people to communicate through voice and video reliably even with variable information rates and from the most difficult-to-reach areas, the demand for them has grown among consumers, businesses, and military agencies.

Topics: Machining, Ardel News

The Latest Addition to Our Equipment Line: Haas EC-400

Posted by Mike Sterling

Nov 2, 2020 5:09:54 PM

Topics: Machining, Ardel News

Ardel Engineering is an ITAR registered CNC machining shop dedicated to providing precision parts and components for military and defense technologies.

ITAR, or the International Traffic in Arms Regulations, is a series of controls designed to restrict and regulate the export of products with defense industry applications.

ITAR, or the International Traffic in Arms Regulations, is a series of controls designed to restrict and regulate the export of products with defense industry applications.

Topics: Ardel News, itar, Manufacturing Certifications

To continue to provide our customers with the superior precision parts they have come to expect from us, we are consistently working toward upgrading and maintaining the latest technology available.

Utilizing state-of-the-art equipment enables us to serve a wide range of industrial customers with the quality and close tolerance parts required for their applications.

Utilizing state-of-the-art equipment enables us to serve a wide range of industrial customers with the quality and close tolerance parts required for their applications.

Topics: Ardel News

Examining the Supply Chain: Pursuing Longer-term Partnerships

Posted by Mike Sterling

Oct 25, 2013 5:34:00 AM

There are many factors that contribute to a manufacturing business’s success; quality of product, customer service, proper and current equipment, necessary certifications, and many other things are all factors in the ever-changing algorithm of successful business strategy.

However, a recent article I read got me thinking about a major factor that I’d like to take some time here in our blog to examine: supplier relationships.

However, a recent article I read got me thinking about a major factor that I’d like to take some time here in our blog to examine: supplier relationships.

Topics: Ardel News, Manufacturing news

For over 40 years, Ardel has stayed at the top of our profession by never settling for second best and never standing still.

We are a leading customer-exclusive production-based job shop because we have never stopped growing and innovating.

We are a leading customer-exclusive production-based job shop because we have never stopped growing and innovating.

Topics: Ardel News

Going on 50 Years of Building Quality Components for Industry

Posted by Mike Sterling

Nov 12, 2012 9:12:00 AM

Ardel Engineering got its start as the brainchild of two General Mills engineers, Del Jensen and Loren Meredith.

In their daily goings-about at General Mills, Del and Loren observed – and astutely so – that the machinery they operated at the company’s plants could be built from higher-quality components. After some negotiations with the parent company, they began fabricating machined parts for General Mills in 1967. Other commercial customers followed in swift succession. In the 1980s, with the massive build-up of the United States Navy to counter the perceived threat of the Soviet Red Banner Fleet, Ardel became a critical provider of high-grade components for U.S. naval warships. Our work on behalf of the U.S. Navy played its fair share in helping America out-engineer and outspend the Kremlin in terms of defense, and allowed for the Cold War to finally – and peacefully – end.

In their daily goings-about at General Mills, Del and Loren observed – and astutely so – that the machinery they operated at the company’s plants could be built from higher-quality components. After some negotiations with the parent company, they began fabricating machined parts for General Mills in 1967. Other commercial customers followed in swift succession. In the 1980s, with the massive build-up of the United States Navy to counter the perceived threat of the Soviet Red Banner Fleet, Ardel became a critical provider of high-grade components for U.S. naval warships. Our work on behalf of the U.S. Navy played its fair share in helping America out-engineer and outspend the Kremlin in terms of defense, and allowed for the Cold War to finally – and peacefully – end.

Topics: Ardel News

Being an ISO-certified, long-proven manufacturer of components for aerospace, we at Ardel wanted to inform our blog readers on one of the more recent trends in aircraft design.

We’re not talking about the fact you have to pay for your “complimentary” audio headset on most flights these days. We’re talking about reducing the overall tonnage of airplanes in order for them to attain greater mechanical performance and efficiency.

We’re not talking about the fact you have to pay for your “complimentary” audio headset on most flights these days. We’re talking about reducing the overall tonnage of airplanes in order for them to attain greater mechanical performance and efficiency.

Topics: Ardel News, Aerospace

Subscribe to Email Updates

Recent Posts

Posts by Topic

- Ardel News (14)

- Manufacturing news (11)

- Aerospace (8)

- Machining (8)

- Medical manufacturing (6)

- Manufacturing for the Military (4)

- 3d printing (3)

- ISO Certification (3)

- itar (3)

- machining complex parts (3)

- Ardel Engineering & Manufacturing (2)

- CNC Machining (2)

- Manufacturing (2)

- Manufacturing Certifications (2)

- Medical Devices (2)

- Military (2)

- additive manufacturing (2)

- horizontal milling (2)

- vertical milling (2)

- CNC Swiss Machining (1)

- Delrin (1)

- GD&T (1)

- Heating and Plating (1)

- PEEK Polymer (1)

- Polyoxymethylene (1)

- aluminum parts (1)

- ebook (1)

- future technology (1)

- military advancements (1)

- military defense (1)

- stainless steel parts (1)

Request a Quote