Precision Aerospace Machining

Aerospace manufacturers use CNC machining to assemble and maintain essential aircraft and space shuttle components. Because a single imperfection or malfunction can lead to disastrous results in aerospace applications, OEMs in this industry rely on CNC machining to eliminate the risk of human error while creating high-precision components under tight deadlines.

CNC machinery can operate with even the highest-quality metals, manufacturing aerospace parts that can withstand the intense pressures and temperatures inherent to these critical applications. We at Ardel Engineering are deeply aware of the many benefits CNC machining brings to the aerospace manufacturing field, which is why we’ve made this manufacturing technique central to our production processes.

Our aerospace machine shop uses some of the most precise and innovative techniques available to create top-quality components for the aerospace field. We work within a strict climate-controlled environment to build products to tight tolerances, and we strive to anticipate and overcome any challenge our components might face in the field.

An Ever Growing Industry

The aerospace industry encompasses many market areas. It involves the design and manufacturing of aircraft and spacecraft, as well as missiles and other components used in the earth's atmosphere and surrounding space. There is a constant demand for highly precise components within this industry as even the smallest imperfection can result in costly damages or danger to human life. Precision is also crucial in ensuring optimal functionality under high-altitude and high-pressure conditions.

To achieve the maximum amount of accuracy possible, mechanical components for the aerospace industry are typically produced through CNC machining. Aircraft and aerospace markets that rely on machining services and machined parts include:

Military aircraft

Precision parts are required in the production of military aircraft, such as fighter jets and transports for moving military equipment and personnel to deployment locations.

READ MORE +

Missiles

Missile bodies are machined using types of CNC equipment specially suited for long components. The precision machining equipment used in this application typically requires high torque in order to mill the hard materials missiles are comprised of.

READ MORE +

Spacecraft

Highly precise machined parts are required to produce components used in space vehicles, the International Space Station, and other aerospace equipment used to land on planetary bodies.

READ MORE +

Commercial airline

Many airplane components are produced using CNC machining, such as landing gear, motion controls, turbines, actuators, and more.

READ MORE +

General aviation

Beyond commercial airlines, there are many general aviation applications for precision machined components, such as in the manufacturing of helicopters, airplane fuselage parts, wing ribs, jet engine casings, and more.

READ MORE +

Materials for Aerospace Machined Parts

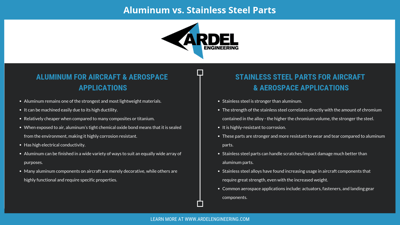

The aerospace industry has strict specifications for the materials used in its component manufacturing. Generally, the materials should be strong and durable while remaining fairly lightweight. One of the most popular materials throughout all market areas of the aerospace industry is aluminum. Aluminum is the third most abundant element on earth, and its abundance makes it a very cost-effective material option. While its hardness and strength vary according to its series, aluminum remains easy to shape and machine. It is widely used in aerospace applications as it meets stringent industry requirements while lowering manufacturing costs.

There are several aluminum alloys that are particularly well suited for aerospace applications, including but not limited to:

- Aluminum Alloy Series 2xxx. Aluminum in this series has been alloyed with copper. These alloys feature high strength, excellent machinability, and good workability. Common applications for this series include wing and fuselage structures due to its good strength-to-weigh ratio.

- Aluminum Alloy Series 6xxx. This is a very versatile series of aluminum alloys. Combined with silicon and magnesium, alloys in this series offer good formability, medium strength, and corrosion resistance.

- Aluminum Alloy Series 7xxx. Containing zinc as the primary alloying element along with copper, chromium, and magnesium, this series displays high strength and is used throughout defense and aviation industries for military aircraft.

Applications

There are many applications for precision machined parts within the various aerospace industry markets. Some of the most common component applications include:

Parts for oxygen generation

READ MORE +

Seats

READ MORE +

Turbine blades

READ MORE +

Shafts

READ MORE +

Valve components

READ MORE +

Electrical connectors

READ MORE +

Housings

READ MORE +

Castings

READ MORE +

Structural components

READ MORE +

Filter bodies

READ MORE +

Ardel works with some of the world’s leading aircraft companies, from Lockheed-Martin to Boeing and Vickers to World Aerospace. Our experience has granted us expansive knowledge regarding the industry and what aerospace professionals need to make their equipment soar.

Partnering with the World’s Leading Aerospace Companies Since 1963

Our aerospace machine shop can work with a variety of metals commonly used in the aerospace field. We can source all metals and other materials from your approved vendor or from our partners, who can supply actual mill certifications. All Fair Article Inspection Reports (FAIR) are completed using AS9102 forms to ensure full project requirements are understood and met. With our ISO 9001:2015 certification and the use of our Zeiss CMM and ROI Vision System to log SPC and CPK data, we guarantee that our finished products will achieve optimal performance no matter their end use.

Ardel works with some of the world’s leading aircraft companies, from Lockheed-Martin to Boeing and Vickers to World Aerospace. Our experience has granted us expansive knowledge regarding the industry and what aerospace professionals need to make their equipment soar.

We understand the critical nature of aerospace machining components. Our team pays the highest levels of attention to the details that make aircraft fly. That’s why we’ve outfitted our shop with dozens of machines specifically designed to produce quality and precise parts.

Our superior aerospace machining capabilities set us apart from the pack and have rendered us a leading service provider in one of the world’s most innovative industries. We actively work to put our team’s experience and our state-of-the-art equipment to good use. We always aim to manufacture high-quality aerospace components that meet our clients’ specifications.

Ardel Engineering & Manufacturing guarantees parts and assemblies of the highest quality. Our manufacturing and controls processes ensure that we achieve nothing less than perfection with all our products.

If you would like to learn more about Ardel’s machining capabilities, contact us or request a quote today.