Over the years, satellite communication systems—also known as satcom systems—have become increasingly important to our day-to-day lives. Since they allow people to communicate through voice and video reliably even with variable information rates and from the most difficult-to-reach areas, the demand for them has grown among consumers, businesses, and military agencies.

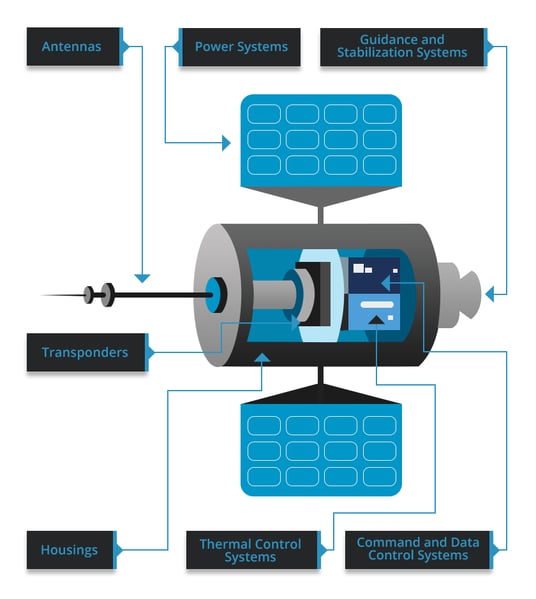

Parts of a Satellite Communication System

Satellite communication systems consist of space-based components and earth-based components, all of which work together to transfer, receive, and process the signals needed for communication. Key components include:

-

Antennas. These components receive and transmit signals between Earth and the satellite.

- Command and data control systems. These components are used to monitor and control the satellite from Earth.

- Guidance and stabilization systems. These components are used to monitor the position of the satellite to ensure it stays in the right orbit and orientation.

-

Housings. These components protect the sensitive satellite components from the harsh conditions in space.

-

Power systems. These components provide energy to the satellite.

-

Thermal control systems. These components protect the satellite from extreme changes in temperature.

-

Transponders. These components convert incoming signals and amplify outgoing signals.

Importance of Precision Machined Parts for Satellite Communications

Given the essential role satellite communication systems play in our daily activities, it is important they function and perform as intended. Achieving this goal necessitates carefully designed and constructed components. Each one must be built to a high degree of precision and accuracy. Otherwise, it may not work properly within the assembled satellite. That’s why many satellite manufacturers rely on precision machining for their parts and products. While precisely machined components help satellites operate optimally, imprecisely machined components can cause spotty voice and video communications.

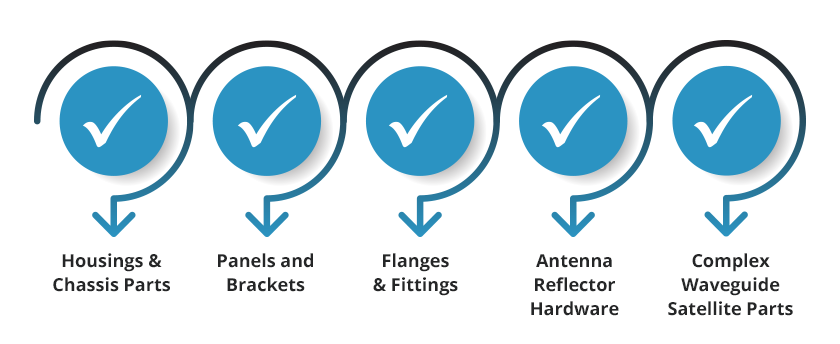

Common Parts for Satellite Communications Systems

Satellite communication systems are made up of many components. The ones that are commonly manufactured using precision machining include:

-

Housings and chassis parts. The chassis provides support and structure to the other satellite components, while the housing protects them from harsh environmental conditions.

- Panels and brackets. The panels and brackets that make up a satellite communication system, both on the ground and in orbit, must be capable of withstanding extended exposure to harsh environmental and operating conditions. Additionally, they must fit cleanly, without gaps or overlap, to prevent the ingress of contaminants.

-

Flanges and fittings. Flanges and fittings must be exceptionally precise and accurate. The smallest gap or inconsistency can reduce the performance and service life of critical satcom equipment.

-

Antenna reflector hardware. Antenna reflectors require fine control to ensure optimal communication between the moving satellite and stationary earthbound receivers. Hardware for these reflectors must therefore be designed, manufactured, and installed with exceptional precision.

-

Complex waveguide satellite parts. The complex arrays used in waveguide satellites must be exceptionally precise to ensure efficient and accurate signal transmission.

Learn More About Precision Machined Satellite Communication System Components From Ardel Engineering

Want more information on precision machined satellite communication system components? Ask the experts at Ardel Engineering. Equipped with extensive experience providing precision machining services to customers in a diverse set of industries, including communications, we can answer or address any questions or concerns you may have about the topic. If you have an upcoming satellite communication system project, contact us to learn about how our precision machining capabilities can benefit you or request a quote to discuss your requirements with one of our team members.