Mike Sterling

Recent Posts

Recent Challenges to Aerospace Parts Manufacturing & Their Solutions

Posted by Mike Sterling

Oct 22, 2021 4:54:50 PM

Topics: Ardel News

While machining technology is always advancing, 2020 accelerated some key innovations. In the machining industry, many companies had to pivot and produce necessary supplies quickly, or they were met with a decreased demand for products and were forced to reduce jobs. Even in the best of times, it's getting more difficult to find manufacturing workers, and companies are turning to automation. Using robotics to increase productivity is one of several trends and changes that are likely here to stay.

Topics: Machining, Ardel News

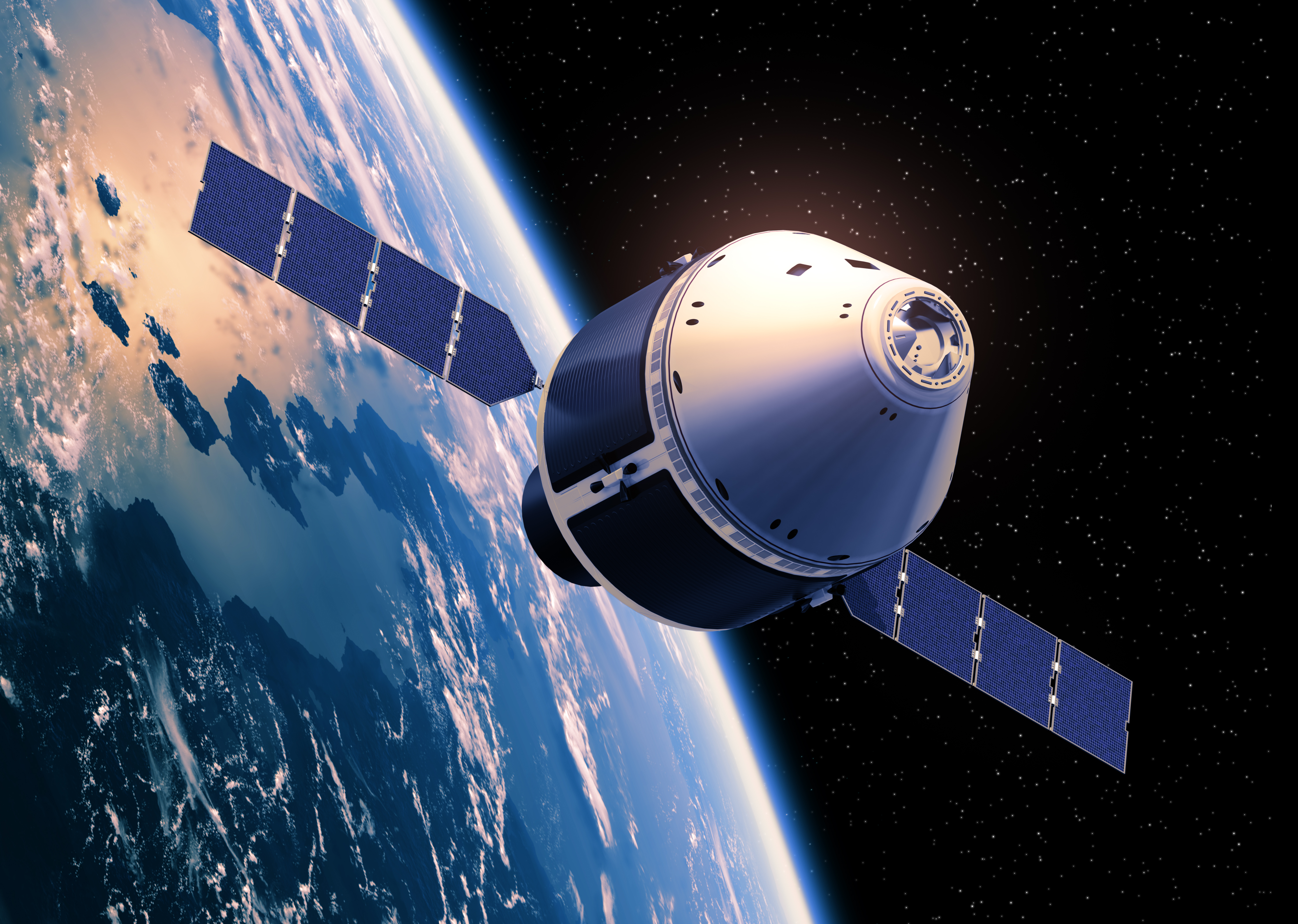

The Role of Machined Components in Satellite Communications

Posted by Mike Sterling

Jun 30, 2021 11:49:44 AM

Over the years, satellite communication systems—also known as satcom systems—have become increasingly important to our day-to-day lives. Since they allow people to communicate through voice and video reliably even with variable information rates and from the most difficult-to-reach areas, the demand for them has grown among consumers, businesses, and military agencies.

Topics: Machining, Ardel News

The Latest Addition to Our Equipment Line: Haas EC-400

Posted by Mike Sterling

Nov 2, 2020 5:09:54 PM

Topics: Machining, Ardel News

Manufacturing 101: Breaking Into the Aerospace Industry

Posted by Mike Sterling

Oct 9, 2020 9:12:26 AM

Topics: Machining, ISO Certification, Aerospace

Computer Numerical Control (CNC) technology has improved the capabilities of many machine shops and manufacturing operations. It's a competitive industry and each company brings its own strengths to the table—but not all contract CNC manufacturers are created equal. It’s important to consider multiple options and select a CNC manufacturer that can handle your project, your budget, and any other unique needs you may have.

Topics: CNC Machining

CNC machining is a manufacturing process known for its versatility. Manufacturers use the process to create high quality, custom-designed parts and products for a wide range of industries from virtually any type of material. Typical machined materials include metal, plastic, wood, foam, and fiberglass.

Topics: Machining

How Vertical Milling Machines Lead to Improved and Diverse Machined Parts

Posted by Mike Sterling

May 21, 2019 10:26:24 AM

CNC vertical milling uses automated processes to control specialized rotary cutting tools that remove material from a workpiece’s surface. Manufacturers use CNC vertical milling to both form a workpiece and to create detailing on its surface. It’s most often used to cut small holes and notches and to create three-dimensional products. These machines’ vertical spindles also make them great for drilling and plunging cuts.

The Importance of CNC Machining in the Communications Industry

Posted by Mike Sterling

Nov 2, 2018 10:08:57 AM

CNC machining refers to Computer Numerical Control, a system that uses computers to control and move a machine. Most often these milling tools are used for metalwork, but they can also make products for a variety of industries.

With the ability to craft sophisticated designs using an assortment of metals, engineers can fabricate precise communications equipment using CNC machining.

Topics: vertical milling, horizontal milling, CNC Machining

Aluminum vs. Stainless Steel Parts for Aerospace Applications

Posted by Mike Sterling

Aug 23, 2018 4:04:31 PM

Aluminum once made up the bulk of the material used in aerospace applications. Aluminum accounts for as little as 20% of the materials used in a typical jet today, however. Composite materials, carbon-reinforced polymers, and honeycomb materials are increasingly seeing usage across the aerospace industry because of the demand for lighter-weight aircraft.

Topics: Aerospace, stainless steel parts, aluminum parts

Subscribe to Email Updates

Recent Posts

Posts by Topic

- Ardel News (14)

- Manufacturing news (11)

- Aerospace (8)

- Machining (8)

- Medical manufacturing (6)

- Manufacturing for the Military (4)

- 3d printing (3)

- ISO Certification (3)

- itar (3)

- machining complex parts (3)

- Ardel Engineering & Manufacturing (2)

- CNC Machining (2)

- Manufacturing (2)

- Manufacturing Certifications (2)

- Medical Devices (2)

- Military (2)

- additive manufacturing (2)

- horizontal milling (2)

- vertical milling (2)

- CNC Swiss Machining (1)

- Delrin (1)

- GD&T (1)

- Heating and Plating (1)

- PEEK Polymer (1)

- Polyoxymethylene (1)

- aluminum parts (1)

- ebook (1)

- future technology (1)

- military advancements (1)

- military defense (1)

- stainless steel parts (1)

Request a Quote