There are many rules and regulations governing the manufacturing sector, including the Defense Production Act, which helps to ensure the military is properly prepared.

The Act was passed in 1950 during the Korean War and was a part of a broad civil defense and war mobilization effort during the Cold War. The Act allows the president to issue executive orders for purchases that need to be completed quickly in order to maintain national security. It allows the president to establish regulations, orders, etc to allocate materials, services, and facilities to promote national defense. Finally, it also authorizes the president to control the civilian economy so that scare or critical materials necessary to national defense are available.

The Act was passed in 1950 during the Korean War and was a part of a broad civil defense and war mobilization effort during the Cold War. The Act allows the president to issue executive orders for purchases that need to be completed quickly in order to maintain national security. It allows the president to establish regulations, orders, etc to allocate materials, services, and facilities to promote national defense. Finally, it also authorizes the president to control the civilian economy so that scare or critical materials necessary to national defense are available.

In our last blog, we talked about the

In our last blog, we talked about the  ITAR stands for “International Traffic in Arms Regulations” and relates to the design, manufacturing process, and sale and distribution of any of these kinds of products.

ITAR stands for “International Traffic in Arms Regulations” and relates to the design, manufacturing process, and sale and distribution of any of these kinds of products. However, a recent article I read got me thinking about a major factor that I’d like to take some time here in our blog to examine: supplier relationships.

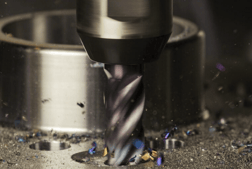

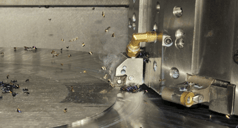

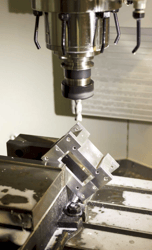

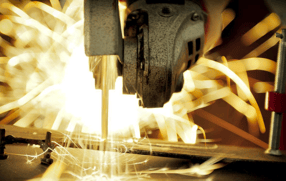

However, a recent article I read got me thinking about a major factor that I’d like to take some time here in our blog to examine: supplier relationships. Lately, there has been a lot of attention and buzz about additive manufacturing, or “3D” printing – we’d like to weigh in on the subject, and also explore other similar technologies from the perspective of a mid-size manufacturer and custom CNC shop.

Lately, there has been a lot of attention and buzz about additive manufacturing, or “3D” printing – we’d like to weigh in on the subject, and also explore other similar technologies from the perspective of a mid-size manufacturer and custom CNC shop. Some are calling it another industrial revolution, but 21st Century style - an advanced manufacturing response to the digital age. There are even those that are expecting and advocating a shift back to the U.S. as being primarily a manufacturing nation, with technology and education joining forces with to create a much larger technically skilled advanced manufacturing labor force. Others argue that the “revolution” isn’t sustainable, and that the next labor revolution should see the service and management sectors dominate.

Some are calling it another industrial revolution, but 21st Century style - an advanced manufacturing response to the digital age. There are even those that are expecting and advocating a shift back to the U.S. as being primarily a manufacturing nation, with technology and education joining forces with to create a much larger technically skilled advanced manufacturing labor force. Others argue that the “revolution” isn’t sustainable, and that the next labor revolution should see the service and management sectors dominate. We are a leading customer-exclusive production-based job shop because we have never stopped growing and innovating.

We are a leading customer-exclusive production-based job shop because we have never stopped growing and innovating.

Speaking at the 2012 Manufacturers’ Summit at the Minneapolis Airport Hilton in Bloomington, MN, Mr. McHale spoke of the “red flag” he saw in outsourcing low-skill manufacturing jobs overseas. While conceding that such a policy wasn’t necessarily a bad thing for America so long as our country took steps to bring advanced manufacturing jobs to its home territory, McHale also noted the perils of off-shoring too many industrial jobs. His reasoning seems reasonable to our own way of thinking here at Ardel: by outsourcing too many low-skill manufacturing jobs to China, Indonesia, and the like, America is giving these countries the incentive to develop advanced manufacturing bases on par with our own. As unskilled labor pools overseas become – by sheer effort and labor – more skilled, the possibility of developing advanced manufacturing jobs to accommodate these new skill-sets is that much more likely.

Speaking at the 2012 Manufacturers’ Summit at the Minneapolis Airport Hilton in Bloomington, MN, Mr. McHale spoke of the “red flag” he saw in outsourcing low-skill manufacturing jobs overseas. While conceding that such a policy wasn’t necessarily a bad thing for America so long as our country took steps to bring advanced manufacturing jobs to its home territory, McHale also noted the perils of off-shoring too many industrial jobs. His reasoning seems reasonable to our own way of thinking here at Ardel: by outsourcing too many low-skill manufacturing jobs to China, Indonesia, and the like, America is giving these countries the incentive to develop advanced manufacturing bases on par with our own. As unskilled labor pools overseas become – by sheer effort and labor – more skilled, the possibility of developing advanced manufacturing jobs to accommodate these new skill-sets is that much more likely. This was back in the 1980s, once upon a time and not so long ago, when the U.S.S.R. was a clear and present danger to the peace of the planet, and the Soviet Red Banner Fleet harbored the largest submarine force in the world. It was a time when slogans for “A six hundred ship Navy!” resounded through the Halls of Congress and the White House. It was a decade that saw the construction of some of the most awesomely powerful ships ever built: the giant Nimitz class aircraft carriers, the deadly and silent Los Angeles-class attack submarines, and the fiercely protective Ticonderoga-class AEGIS missile cruisers. By outspending the Soviet Union in naval forces year upon year, we contributed to Communism’s collapse, and the birth of the so-called Pax Americana. We played our part at

This was back in the 1980s, once upon a time and not so long ago, when the U.S.S.R. was a clear and present danger to the peace of the planet, and the Soviet Red Banner Fleet harbored the largest submarine force in the world. It was a time when slogans for “A six hundred ship Navy!” resounded through the Halls of Congress and the White House. It was a decade that saw the construction of some of the most awesomely powerful ships ever built: the giant Nimitz class aircraft carriers, the deadly and silent Los Angeles-class attack submarines, and the fiercely protective Ticonderoga-class AEGIS missile cruisers. By outspending the Soviet Union in naval forces year upon year, we contributed to Communism’s collapse, and the birth of the so-called Pax Americana. We played our part at