For a machining job shop that does regular contract work with government organizations, some key certifications and qualifications often need to be met.

In our last blog, we talked about the ITAR certification, but there are several more regulations and accreditations that are crucial for work with any job with government involvement or oversight.

In our last blog, we talked about the ITAR certification, but there are several more regulations and accreditations that are crucial for work with any job with government involvement or oversight.

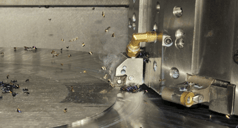

Two particular certifications come to mind as particularly relevant, and regularly specified here at Ardel: NADCAP and DFARS. NADCAP, or National Aerospace and Defense Contractors Accreditation Program, is an accreditation program specific to aerospace and defense applications that covers a host of particular processes. Among these are conventional machining, heat treating, coatings, sealing, and welding, all of which are commonly encountered either on our manufacturing floor or on our jobs. The Defense Federal Acquisition Regulations (DFARS) govern the procurement of materials for any defense contracted job. This is the legal arm for proper procedure for any contracting with the federal government – combined with the NADCAP certification, it serves to position Ardel as a premier manufacturer for any defense or military contracting.

Compliances like these truly streamlines the process for these jobs, and enables us to offer manufacturing services up to a quality and procedural standards recognized by some of the most demanding fields in our space. Make sure to stop back here at our blog for more of our insights into the trends and issues that affect our industry.