We follow all industry certification and compliance guidelines to ensure our customers’ products meet all relevant requirements. Learn more about ITAR compliance and what organizations need to be ITAR-registered.

What Is ITAR?

The International Traffic in Arms Regulations (ITAR) is a set of guidelines that regulate the export of products and services with military industry applications.

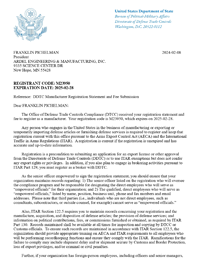

The U.S. Department of State is in charge of ITAR and determines what products and services require ITAR compliance according to the United States Munitions List (USML). The goal of ITAR is to prevent unclassified defense-related goods from falling into the possession of unfriendly governments or other groups.

ITAR consists of multiple implications for companies that manufacture, sell, or import/export defense-related products. Any company with access to any defense-related goods, services, or technical information must comply with ITAR and be licensed by the U.S. State Department.

Munitions, weapons, and military vehicles are apparent examples of military articles. But defense-related personnel equipment, shelters, technical data, software, and services like repairs, maintenance, and testing also fall under ITAR’s oversight.